CS SERIES SUPPORT

We’ve got you covered!

Our EvoHeat’s tech support pages contain extensive information on installation and operation of your EvoHeat unit. For further technical support please contact 1300 859 933.

Below is a list of topics where you will find lots of helpful videos, tips and technical support information on our EvoHeat CS heat pumps.

Troubleshooting

My unit isn’t working

- Is the screen of control panel lit? If not, make sure the electrical wires and cables are correctly connected and the power is on. Ensure any circuit breaker devices are set to the ON position and press the ON button on your controller. Check your controller cable is plugged in and is not damaged. If the unit has been shut off or the power has been interrupted the heater will not restart for a 5-minute period to protect the compressor. Wait 5 minutes before attempting a restart.

- Is there sufficient water flow? If the screen displays a water flow related error check the water flow. Is the water pump in operation and the system free of debris that may cause a blockage? Disconnect pool cleaners to ensure proper water flow.

- Is the current pool/spa water temperature higher than the set temperature on the controller? If so the unit will not operate until the pool/spa water temperature falls below the set temperature on the controller.

- Check the unit is set to run at the correct time and date. Please check your current timing or temperature modes on your controller – you may have programmed the unit to turn on at a different time.

- Check the controller for error messages and refer to table below.

My unit is running but not heating

- Is the fan functioning? If not contact EvoHeat tech support on 1300 859 933

- Is the air discharged from the top of the fan noticeably cooler than the ambient temperature? If not, check the refrigerant gauge on the bottom panel of the heater. Another way to determine if the heater is working correctly is to look at the controller’s screen and check to see if the WATER OUT temp is higher than the WATER IN temp. Check also the INLET WATER TEMP is lower than the HEAT TEMP set point. If the gauge shows less than 0.8MPA (the outside black band) contact EvoHeat tech support to check the refrigerant system.

- Ensure sufficient fresh airflow around the unit as per installation instructions. Make sure cold air discharged does not recycle back through the heater. Check the condenser fins. If they are dirty or blocked use a low flow garden hose only (Pressurised water may cause damage to the heater).

- The unit will periodically defrost when the ambient air temperature is lower than 8 degrees C.

My heater is running continuously

- Check the set temperature is at your desired level and that the pool water temperature is at or below this set point.

- Possible electrical component failure – contact EvoHeat tech support on 1300 859 933

Water appearing around unit base

- Condensation is a normal by product of running a pool heat pump.

- Possible water leak. Check the discharge for the presence of chlorine. If the water has no chlorine then it is condensation and is normal. Another method of checking is to turn the heater off and run the water pump continuously for a period of 2-4 hours. If the water dries out then it was condensation. If there is a continuous leak contact EvoHeat tech support on 1300 859 933.

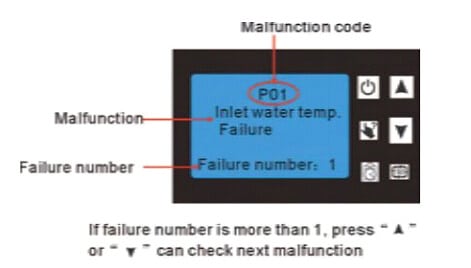

What will the controller display if my unit malfunctions?

Error Codes

My heater is displaying an error code

| CODE | FAILURE | REASON | SOLUTION |

|---|---|---|---|

| Power on | |||

| Normal working | |||

| P01 | Inlet temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp. sensor |

| P02 | Outlet temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp. sensor |

| P04 | Ambient temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P15 | System 1 coil temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P25 | System 2 coil temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P35 | System 3 coil temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P45 | System 4 coil temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P17 | System 1 absorb temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P27 | System 2 absorb temp sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P37 | System 3 absorb temp sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P47 | System 4 absorb temp sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P19 | System 1 anti-freezing temp sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P29 | System 2 anti-freezing temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P39 | System 3 anti-freezing temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P49 | System 4 anti-freezing temp. sensor failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P191 | Using side system 1 anti-freeze temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P291 | Using side system 2 anti-freeze temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P391 | Using side system 3 anti-freeze temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P491 | Using side system 4 anti-freeze temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P151 | System 1 coil inlet temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P251 | System 2 coil inlet temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P351 | System 3 coil inlet temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| P451 | System 4 coil inlet temp failure | The temp sensor is broken or short circuit | Check or change the temp sensor |

| E05 | System protection | The protection system has failed | Check each protection point of the system |

| E08 | Communication Failure | Communication failure between wire controller and main board | Check the wire connection between remote wire controller and main board |

| E11 | High pressure 1 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E21 | High pressure 2 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E31 | High pressure 3 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E41 | High pressure 4 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E12 | Low pressure 1 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E22 | Low pressure 2 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E32 | Low pressure 3 Protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E42 | Low pressure 4 protection | The high-pressure switch is broken | Check the pressure switch and cold circuit |

| E03 | Water flow failure | No water/little water in water system | Check the pip water flow and water pump |

| E04 | Electrical-heat over heat failure | Electrical-heat is over heat | Check or change electrical-heat |

| E06 | Water-inlet and outlet temp. difference | Water flow is not enough and low differential pressure | Check the pipe water flow and whether the water system is jammed or not |

| E06 | System 1/2/3/4 anti-freeze protection | Water flow is not enough and low differential pressure | Check the pipe water flow and whether water system is jammed or not |

| E171 | The system 1 use side anti-freezing protection | Water flow is not enough | Check the pipe water flow and whether the water system is jammed or not |

| E271 | The system 2 use side anti-freezing protection | Water flow is not enough | Check the pipe water flow and whether the water system is jammed or not |

| E371 | The system 3 heat source side anti-freezing protection | Water flow is not enough | Check the pipe water flow and whether the water system is jammed or not |

| E471 | The system 4 heat source side anti-freezing protection | Water flow is not enough | Check the pipe water flow and whether the water system is jammed or not |

| E19 | The primary anti-freezing protection | The ambient temp is low | / |

| E29 | The secondary anti-freezing protection | The ambient temp is low | / |

BHB10 Malfunction Codes

| CODE | FAILURE | REASON | SOLUTION |

|---|---|---|---|

| P181 | Discharge 1 temp. sensor failure | The sensor is open or short circuit | Check or change the sensor |

| P281 | Discharge 2 temp. sensor failure | The sensor is open or short circuit | Check or change the sensor |

| P04 | Ambient temp. sensor failure | The sensor is open or short circuit | Check or change the sensor |

| E171 | System 1 anit-freeze temp. failure | The sensor is open or short circuit | Check or change the sensor |

| E271 | System 3 anti-freeze temp. failure | The sensor is open or short circuit | Check or change the sensor |

E03 Error Code

The E03 error is not an issue pertaining to the heat pump itself, and is usually a rather simple fix. This error means that there is little or no water flow getting to the unit and is just a safety precaution for your heat pump.

If the heat pump is off and displaying an E03 error, this is normal and when the system is turned on and water flow resumes the error will disappear.

Things that can cause an E03 error include:

- The water pump not being on

- Valves not being in place correctly

- Blockages due to debris in the skimmerbox, pump or filter

What you can do to try and clear this error yourself:

- Make sure the water pump is on

- If there is a bypass installed, see if too much water is being bypassed

- Ensure all valves are in place correctly

- Check for blockages in the skimmerbox, pump, filter or the provision for heating suction point.

Some other things to consider that may help find the cause of the error:

- See if the water pump is making any scratchy or grinding noises

- Is there any air in the water pump viewing window?

- When was your last backwash completed? (If the heater is connected in-line with the filtration system)

If after checking and trying all suggestions and you are still getting an E03 error, call EvoHeat’s technical support on 1300 859 933 for assistance.

Maintenance

Do I need to get my unit serviced? It is recommended that you get your EvoHeat unit serviced once a year by your local certified air conditioning or refrigeration technician. If your unit is located in a coastal area, more frequent maintenance may be necessary. During the service, they will check the operational pressures of the refrigeration system and give the unit and fins a good clean to ensure maximum performance.

Do we have recommended service agents? EvoHeat have a large database of recommended service agents. Please contact EvoHeat tech support on 1300 859 933 for your local service agent details.

Should I check my unit regularly? We recommend you check your unit regularly to avoid potential issues and damage to your heat pump.

What should I be checking regularly? Check the water inlet/outlets often for leaks. You should avoid the condition of no water or air entering into the system, as this will influence unit’s performance and reliability. You should clear the pool/spa filter regularly to avoid damage to the unit as a result of the dirty of clogged filter. The area around the unit should be dry, clean and well ventilated. Make sure there is nothing blocking the airflow of the heater e.g. Leaf litter. Discharge all water in the water pump and water system, so that freezing of the water in the pump or water system does not occur. You should discharge the water at the bottom of water pump if the unit will not be used for an extended period. You should check the unit thoroughly and fill the system with water fully before using it for the first time after a period of time. Check the power supply and cable connection often, should the unit begin to operate abnormally, switch it off and contact the qualified technician.

Energy Saving Tips

If your pool water is allowed to cool significantly, it may take several days to return to the desired swimming temperature. For weekend use, it is more economical to maintain the pool water temperature at or near your desired swimming temperature. If you do not plan to use your pool for a prolonged period, then you might choose to turn the heat pump completely off or decrease the temperature setting of the control several degrees to minimize energy consumption.

- Use an accurate pool thermometer. A difference of 2ºC, between 26ºC and 28ºC, will significantly increase energy consumption.

- Carefully monitor the water temperature of your pool in the summer time. You can reduce heat pump usage due to warmer air temperatures.

- When the pool is not used for long periods, turn off the heat pump.

- Where possible, shelter the pool from prevailing winds with well-trimmed hedges or other landscaping, cabanas, or fencing.

- Always use a high-quality pool cover when practical. Besides providing a valuable water saving feature, a pool cover will dramatically reduce heat loss and reduce your pool heating running costs by up to 70%.

COMPANY

SUPPORT

EvoHeat means smarter living through energy saving. Contact Us today!

© Evo Industries Australia Pty Ltd. All Rights Reserved. Privacy Policy

Website designed and developed by Balar Media Group.